Uncompromising Quality

Quality is a driving force within our organization. We have implemented and refined quality systems to provide structure to every phase of manufacturing, from initial quotations to the final shipment of product to our customers. Our quality systems include:

- 4 – Quality labs throughout the plant

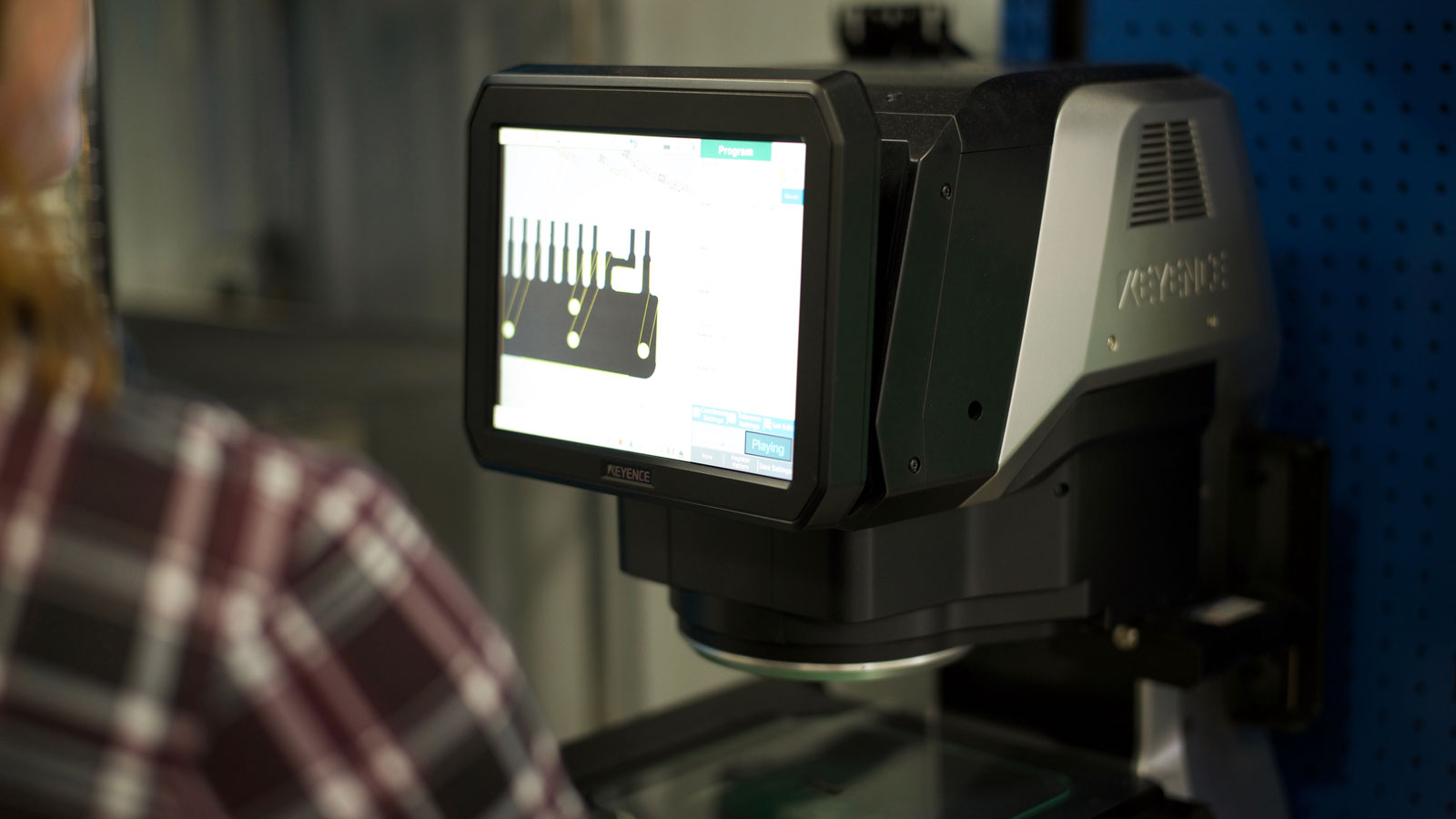

- 3 – CMM’s, 4 – OGP Flash 500’s, 4 – OGP 302’s, 1 – OGP Quest 450 and 2 – OGP 250’s

- Staffing dedicated to component development, in-process inspection, and final inspection and documentation

- SPC on the shop floor and smart work stations are utilized in production areas to allow the operator to collect real time data using QC-Gage

Quality Systems

Brunk uses a comprehensive enterprise quality management software package (IQS) to unify and accommodate all facets of our quality process. IQS provides all Brunk employees access to every element of the quality management system. Procedures, process data and records are all accessible, allowing for instant retrieval of information at the point of use. This provides excellence in quality that is unmatched.

Quality and Testing for Precision Manufacturing

At Brunk, we empower clients to achieve unparalleled quality and precision in manufacturing through advanced systems, expert metrology, and meticulous execution. Precision manufacturing requires components that adhere to stringent tolerances, perform consistently, and integrate smoothly into intricate systems. Achieving this consistency necessitates a systematic approach to quality production, precise measurements, and quality control throughout design, production, and delivery. This guide details how quality assurance frameworks, innovative testing methods, and continuous improvement practices collectively ensure consistent excellence on the production floor. It also highlights why Brunk is a reliable partner for quality assurance in meeting industry standards.

Key Aspects of Quality Assurance in Precision Manufacturing

Quality assurance (QA) comprises the set of policies, procedures, and controls ensuring products meet defined specifications and customer requirements. In precision settings, even slight deviations in dimensions, surface finish, or material properties can result in performance issues, safety risks, or costly rework, making QA vital for quality production and control outcomes.

An effective QA program involves documented processes and work instructions, thorough design and process validation, supplier quality management, incoming and in-process inspections, calibration and preventive maintenance, employee training with competency tracking (including NIMS-aligned skills), and corrective and preventive action systems. These elements emphasize defect prevention over detection, reinforcing quality checks at every manufacturing stage.

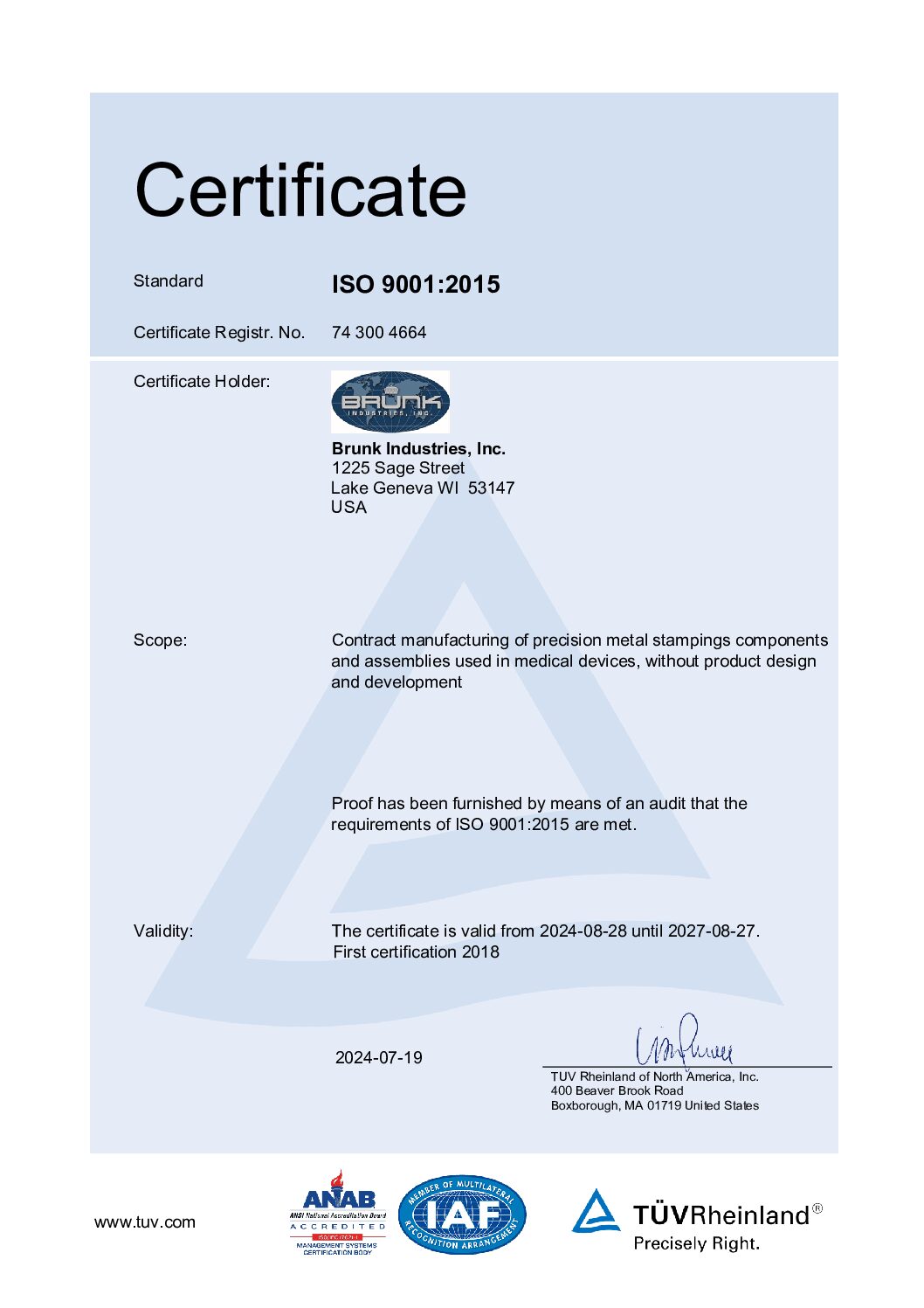

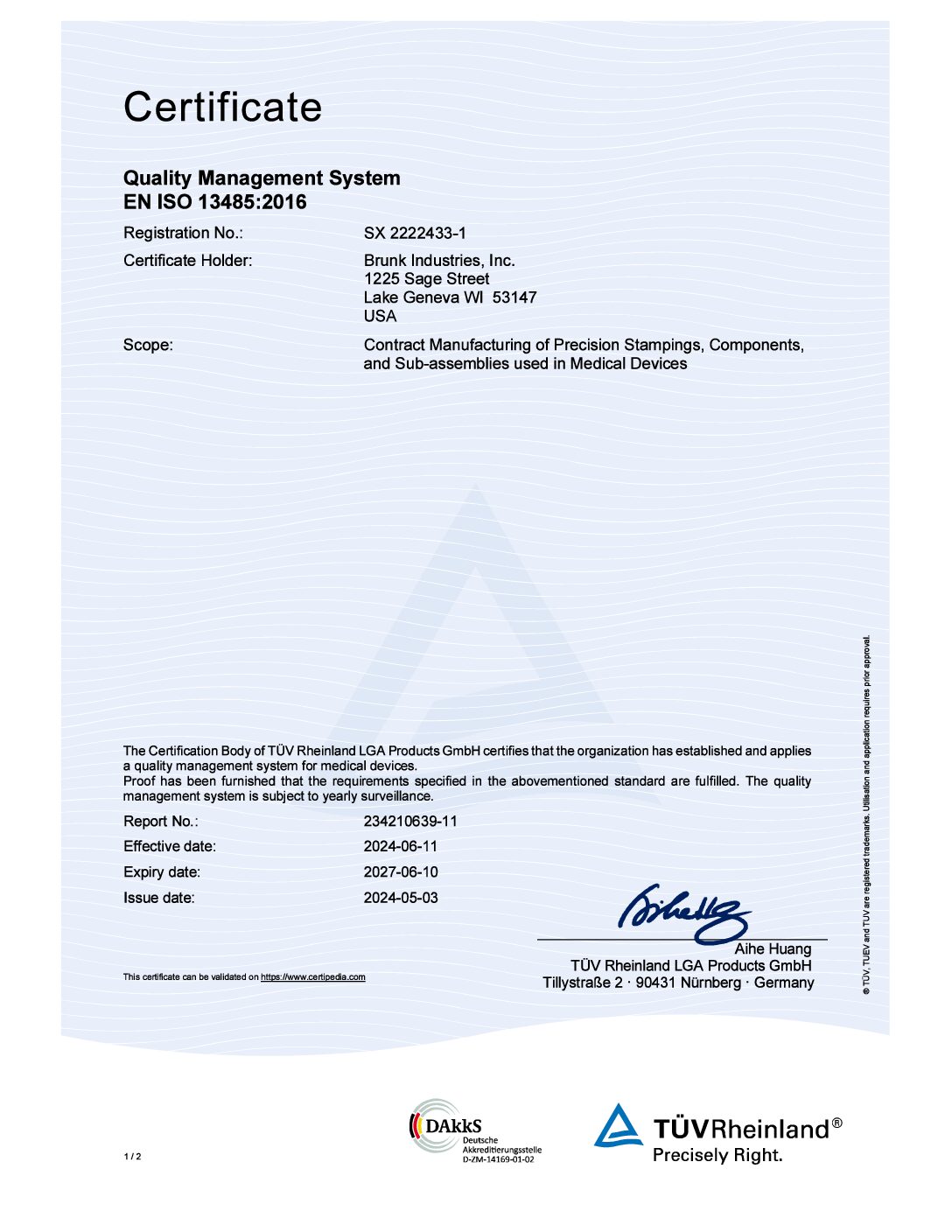

Standards and certifications offer a common framework for quality. ISO 9001:2015 sets a general quality management framework, while ISO 13485:2016 pertain to medical devices. For measurement systems, ISO/IEC 17025 supports laboratory competence. In regulated markets, FDA expectations require documented evidence of medical-grade materials, process validation, and robust traceability. Certification to ISO 9001:2015 and ISO 13485:2016 signifies strong governance and continual improvement, aligning expectations among customers, suppliers, regulators, and the FDA. Brunk adheres strictly to these frameworks, establishing our team as a dependable leader in manufacturing quality control.

Advanced Testing Techniques in Precision Manufacturing

Testing ensures parts conform to specifications and function as intended. Common techniques include:

- Dimensional inspection using CMMs, optical comparators, laser scanners, advanced digital microscopes, OGP optical 3D measurement systems and micrometers for precise measurements

- Material and mechanical testing, including hardness, tensile, fatigue, and microstructure analysis of medical-grade materials

- Surface and geometric evaluation of roughness, flatness, roundness, and profile

- Functional testing that replicates operating conditions to verify performance and reliability

Choosing the appropriate technique depends on the manufacturing process, risk profile, and critical quality attributes. For intricate stamped geometries, a calibrated vision system is optimal, while laser scanning is ideal for freeform surfaces. Consider tolerance bands, material type, surface accessibility, production volume, and cost when selecting methods, and validate measurement uncertainty via MSA to ensure reliable results. Brunk employs standardized MSA practices to confirm measurement systems are capable and repeatable.

Emerging technologies enhance accuracy and efficiency. Automated metrology cells reduce measurement cycle times and variability. In-line vision systems enable 100% inspection on high-throughput lines. Digital twins and model-based definitions link CAD, CAM, and inspection data to prevent interpretation errors. Automated defect recognition speeds up sorting, while IoT-enabled equipment streams data for real-time process adjustments. These advancements shorten feedback loops, minimize scrap, and improve traceability—key benefits of Brunk’s precision manufacturing quality and testing programs.

Continuous Improvement: A Cornerstone of Quality Control

Quality control monitors and adjusts processes to keep outputs within specification. Continuous improvement fortifies quality control by systematically reducing variation and eliminating waste. Proven methods include Six Sigma and Lean Six Sigma to address defect root causes, Statistical Process Control to monitor key variables, Design of Experiments to optimize parameters, standardized work to stabilize processes, and mistake-proofing to prevent errors at the source.

Data and metrics guide improvement initiatives. Monitor defect rates, Cp/Cpk for process capability, MSA results, on-time delivery, and cost of quality. Use control charts to detect trends, Pareto analysis to prioritize key issues, and real-time dashboards for rapid responses. CAPA ensures corrective actions are effective, institutionalized, and align with FDA and ISO 13485 expectations for medical quality. Our approach combines disciplined analysis with shop-floor engagement to enhance measurement components, improve precision measurements, and boost overall capability.

These examples demonstrate how precise measurement, cross-functional collaboration, and iterative learning achieve sustainable improvements in precision manufacturing. Partnering with Brunk provides access to a trusted leader with proven systems for industry-specific quality control, comprehensive quality checks, and end-to-end quality and testing—ensuring precision, reliability, and confidence from prototype to production.

Quality Certifications

Contact our sales team to discuss your next project.