Laser Welding for Medical and High-Tech Industries

Laser welding is a critical joining method for advanced manufacturing where precision, cleanliness, and repeatability are mandatory. At Brunk, we apply tightly controlled laser energy to join metals and alloys used in medical devices and high-tech assemblies, producing narrow, consistent welds with minimal distortion. As a trusted leader, Brunk delivers laser welding benefits through validated processes and rigorous quality systems. Below, we explain how laser welding works, why it excels in regulated and mission-critical environments, and where it delivers the greatest value across medical welding and technology applications. This page is dedicated to laser welding for medical and high-tech industry needs, including welding medical devices and related high-tech assemblies.

Understanding Laser Welding

Laser welding uses a focused light beam to locally heat and fuse materials along a defined joint. High energy density enables rapid melting and solidification, creating fine welds with minimal thermal impact on adjacent features. Conduction mode suits thin sections, while keyhole mode supports deeper penetration. Brunk’s expertise in medical device laser welding ensures tight control of heat input and geometry for sensitive components.

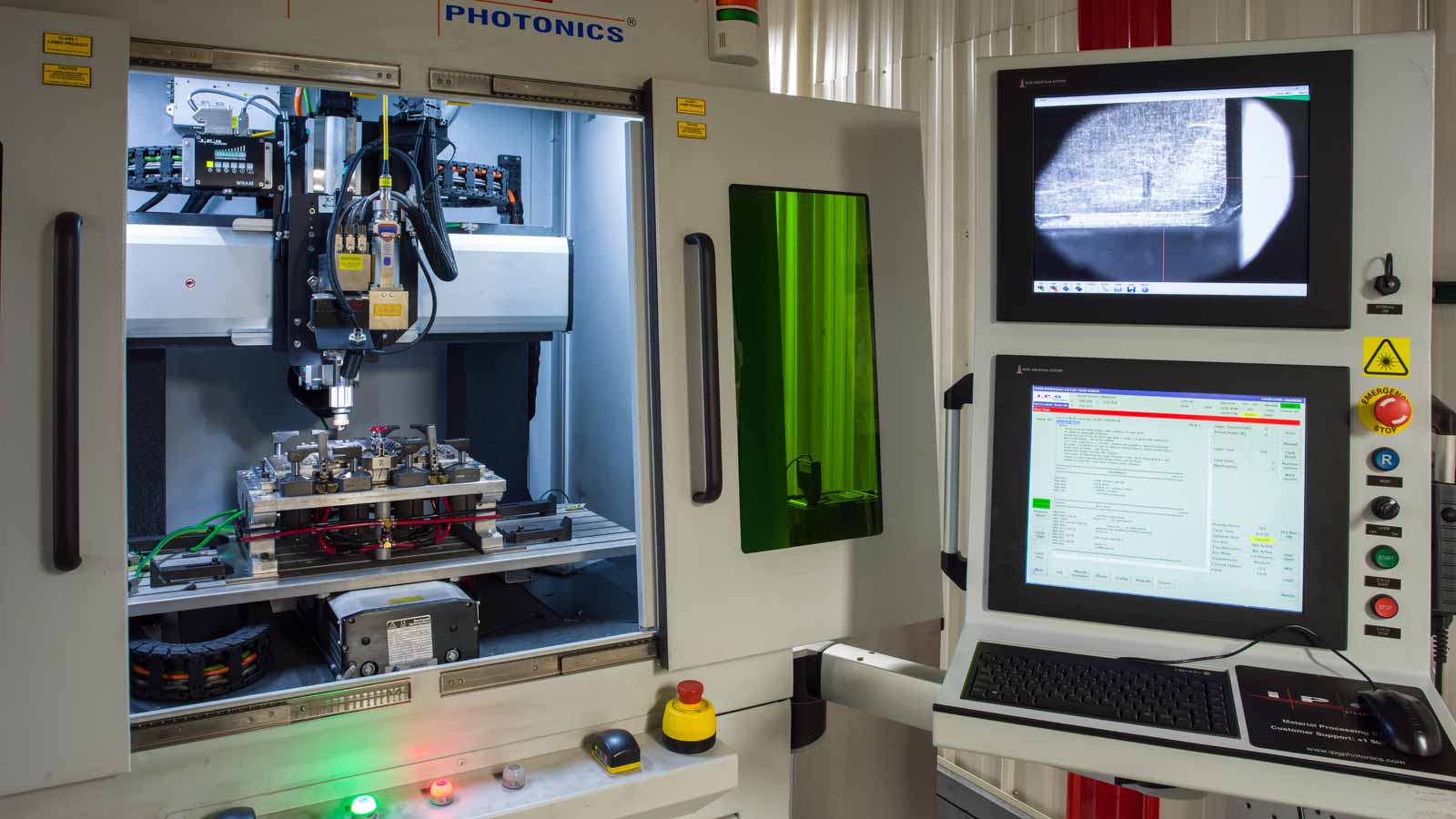

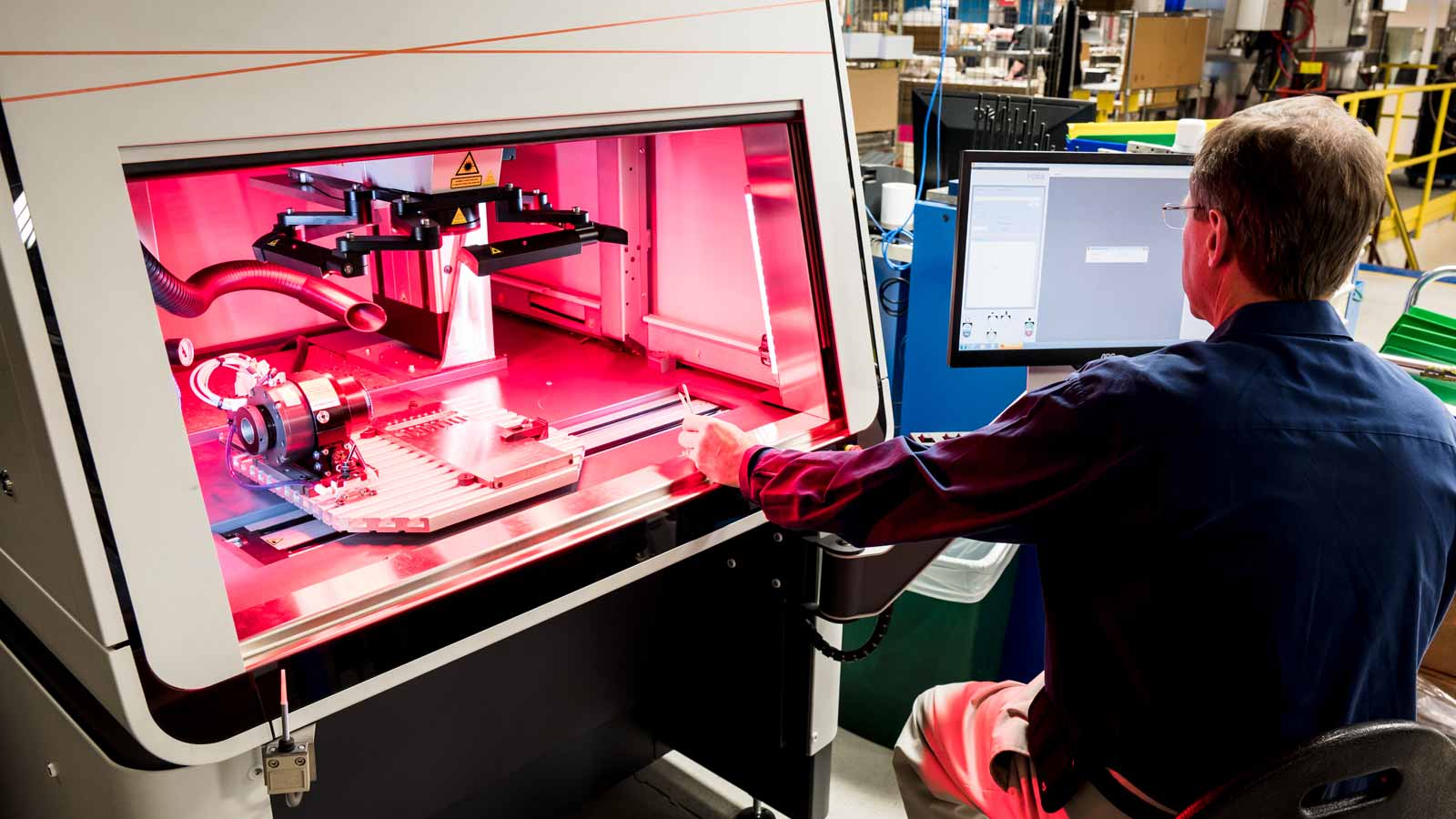

Compared with TIG or resistance welding, laser welding offers non-contact energy delivery, precise heat input, and highly consistent micro-scale welds, often without filler. The process integrates well with automation, vision guidance, and real-time monitoring to cut variability and rework—core advantages of laser welding that Brunk leverages to deliver repeatable outcomes. These laser welding benefits are particularly valuable when welding medical devices and other tightly toleranced parts.

Common laser sources for medical and high-tech manufacturing include fiber lasers for precision and efficiency, pulsed Nd:YAG lasers for small features and heat-sensitive parts, and diode lasers for compact, reliable systems. Selection depends on material, thickness, joint design, and regulatory requirements for the finished product. Our engineering team aligns source selection with the demands of laser welding for medical and high-tech industry programs as well as adjacent sectors such as automotive laser welding.

Advantages in Medical and High-Tech Applications

Laser welding delivers measurable benefits where accuracy and cleanliness drive performance and compliance. Brunk’s process development focuses on unlocking advantages of laser welding that matter most to regulated markets:

- Precision and accuracy: Tight beam control enables micro-welds on tiny components, intricate seams, and edges near delicate features—ideal for welding medical microassemblies.

- Reduced heat-affected zone (HAZ): Concentrated energy limits thermal distortion, preserving metallurgy, coatings, and nearby electronics—key laser welding benefits for medical device laser welding and sensor housings.

- Enhanced process control: Closed-loop power modulation, pulse shaping, and automated motion produce consistent weld geometry and penetration.

- Clean, low-contamination joins: Non-contact energy and controlled atmospheres minimize particulates and spatter, supporting sterility for medical devices and other welding medical applications.

- Scalability and automation: CNC and robotic cells integrate lasers for high throughput with traceable, repeatable results—another of the advantages of laser welding that Brunk provides.

For high-tech assemblies, these advantages enable precise joining of microelectronic housings, thermal management components, and sensor packages without damaging sensitive circuitry or altering performance-critical tolerances. Brunk’s experience also extends to automotive laser welding, applying similar controls to achieve robust, clean welds on complex metal systems.

Laser Welding Applications in Medical and High-Tech Fields

In medical device manufacturing, laser welding is used for catheter components, surgical instruments, endoscopic tools, and hermetic seams for implantable devices such as pacemakers and neurostimulators. The process supports biocompatibility and cleanroom needs while delivering repeatable results on small features. As a leader in welding medical devices, Brunk validates each process to meet stringent performance criteria.

For microcomponents and complex geometries, the narrow beam and fine focus create precise welds on miniature housings, thin foils, and tightly toleranced subassemblies where conventional welding could cause distortion or excessive heat. These laser welding benefits help protect delicate features while meeting dimensional and functional targets.

In implantable and electronic devices, laser welding forms leak-tight, corrosion-resistant joints around battery enclosures, sensor windows, and feedthroughs. These hermetic seals protect electronics from bodily fluids and environmental exposure while meeting stringent reliability targets—core advantages of laser welding in demanding environments. Brunk’s medical device laser welding capability ensures compliance and traceability across programs.

Industries that benefit most include medical devices, microelectronics, aerospace and defense, telecommunications, and precision instrumentation—sectors where dimensional stability, reliability, and documentation are essential. Our expertise also supports automotive laser welding projects that require high throughput with consistent, validated results. Whether welding medical assemblies or high-tech components, Brunk’s team delivers quality and confidence.

Material Considerations for Laser Welding

Typical materials for medical and high-tech laser welding include stainless steel (e.g., 304, 316L), titanium and titanium alloys, nickel-based alloys, cobalt-chromium, and specialty grades used in implantables. Precious metals such as platinum and gold, and certain aluminum and copper alloys, can be welded with tailored parameters and wavelengths.

Material compatibility depends on reflectivity, thermal conductivity, and alloy composition. Highly reflective or conductive materials like copper may require specific laser sources and tuned process parameters. Dissimilar metal joints often need careful joint design and parameter control to mitigate brittle intermetallic formation. Brunk engineers optimize parameters for laser welding for medical and high-tech industry materials and for welding medical devices with challenging combinations.

Surface preparation directly impacts weld quality. Clean, oxide-free surfaces improve energy absorption and reduce defects. Best practices include precision cleaning, controlled atmospheres (e.g., argon), and fixturing that maintains stable focus and alignment. Brunk’s process validation ensures robust welds across approved material sets, reinforcing the advantages of laser welding in production.

Quality Assurance and Regulatory Compliance

Traceability and documentation are vital in medical and high-tech laser welding. Brunk maintains digital records for materials, lot numbers, equipment settings, and operator qualifications, ensuring end-to-end traceability for audits and field performance. Our systems support welding medical programs and high-tech assemblies with reliable data integrity.

Relevant standards and regulations include ISO 13485 for quality management, ISO 14971 for risk management, and guidance aligned with FDA design controls and process validation. For hermetic assemblies, applicable leak-testing standards and sterilization compatibility are addressed during development. These frameworks underpin Brunk’s leadership in medical device laser welding.

Quality control methods include metallographic evaluation, microhardness, tensile and shear testing, helium leak detection for hermetic seals, and non-destructive techniques such as visual magnification and X-ray imaging when appropriate. Statistical process control and parameter monitoring maintain consistency across production runs. These practices deliver the laser welding benefits customers expect from a trusted partner.

Frequently Asked Questions

What is laser welding and how is it used in the medical industry?

Laser welding uses high-energy light to fuse metals with minimal heat spread, producing clean, precise joints. In the medical industry, it assembles surgical instruments, catheter components, implantable device housings, and micro-assemblies requiring biocompatibility and hermeticity. Brunk specializes in welding medical devices with validated, repeatable processes.

What are the advantages of laser welding in high-tech applications?

Key advantages include micro-scale precision, small HAZ for dimensional stability, reliable hermetic seals, compatibility with sensitive electronics, and seamless automation for consistent, high-throughput production. These advantages of laser welding are central to Brunk’s approach to laser welding for medical and high tech industry needs.

What materials can be laser welded for medical devices?

Common options are 316L stainless steel, titanium, nickel-based alloys, cobalt-chromium, and precious metals like platinum. With appropriate process tuning, certain aluminum and copper alloys can also be welded. Brunk’s medical welding expertise ensures the right parameters for each application.

Which industries benefit most from laser welding technology?

Medical devices, microelectronics, aerospace and defense, telecom hardware, precision instrumentation, and automotive laser welding benefit most—particularly where clean, traceable, and dimensionally stable welds are required. Brunk supports these sectors with validated laser welding benefits tailored to their needs.

Contact our sales team to discuss your next project.