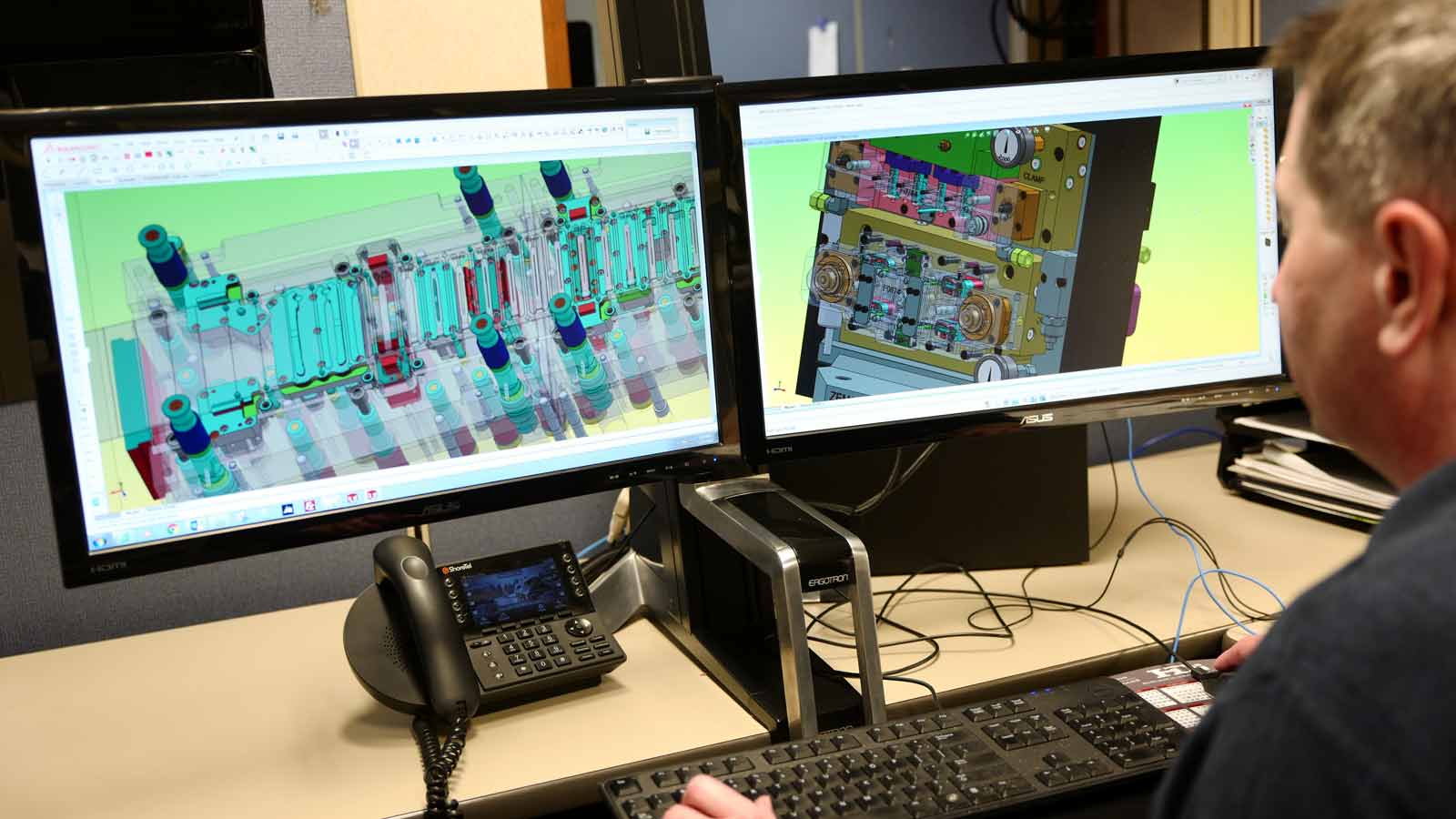

Tool Design Process

Tool Design excellence is a culture at Brunk since 1960. We apply a totally integrated tool design process that flows through all aspects of tool engineering, building, and stamping through assembly. The quality of our finished stamping begins with a collaboration with our customers. This process includes an overview of the manufacturing process, to ensure an ultimate performing tool. Our sophisticated tooling designed by cross-functional teams deliver unmatched precision, efficiency and economical production. Our advanced tool design process combines versatility, longevity, accuracy and reliability, while conforming to exact customer specifications. At Brunk we utilize technical based solutions software including SolidWorks, AutoCAD, and FEA.

Finite Element Analysis – FEA

At Brunk our designs and concepts have offered many of our customers a competitive alternative to traditional technologies such as machining, die casting or MIM. Our design approach which utilizes FEA, combined with advanced press technology, provides the capability to produce precision stampings with complex geometry that exceeds industry standards.

Design for Manufacturing (DFM): Your Fast Track to Production-Ready Design

Design for manufacturing connects smart design decisions with scalable, cost-efficient production. At Brunk, we plug in early with your design engineering team to apply DFMA principles that cut risk, simplify assembly, and accelerate launch timelines. This practical guide covers the essentials—core DFMA and design for additive manufacturing strategies, measurable design metrics, step-by-step integration, and how data and automation reshape manufacturability. You’ll also find common roadblocks and how to avoid them. From rapid prototype to full-scale builds, Brunk keeps your design intent intact while optimizing material selection, standard tooling, and process capability. Partner with a design engineer-led, manufacturing-first organization that gets you ready for volume—confidently and quickly.

What Is Design for Manufacturing?

Design for manufacturing is a structured approach to new product development that aligns engineering intent with how parts are actually produced—at the lowest total cost and the highest reliability. DFMA guides choices in geometry, tolerances, material selection, and assembly so designs move smoothly from solid modeling to the shop floor. With Brunk, design engineers get early manufacturability feedback that reduces complexity, tightens design metrics, and ensures components are ready for machining, molding, machine to stamping, and pcb board fabrication.

DFMA is not a single checkpoint—it’s a continuous practice backed by CAD/CAM, FEA, and production data. Our workflows embed design for manufacturing across concept, validation, and scale-up. That means using FEA to inform wall sections and ribs, choosing stainless steel or 3D printed metal when it benefits durability, and validating process windows with machined prototypes before tooling. The result: predictable outcomes from pilot to volume.

For modern programs, DFMA is essential to speed, resilience, and quality. Early attention to manufacturability eliminates costly redesigns, reduces scrap, and accelerates approvals. Standard tooling and standardized materials improve throughput, while cross-functional collaboration keeps design engineering, quality, and operations aligned. Brunk applies design for additive manufacturing where it unlocks geometry and lead-time advantages, and we balance DFMA with brand, function, and cost targets.

Core DFMA Principles That Deliver

Simplify the design. Clear geometries, accessible features, and appropriate tolerances drive manufacturability and reduce risk. In solid modeling, we remove unnecessary steps, set realistic design metrics, and optimize interfaces for assembly, inspection, and automation. Brunk partners with your design engineer early so CAD decisions fit real processes—molding, machine to stamping, pcb board fabrication, and additive builds.

Standardize wherever possible. Selecting common fasteners, finishes, and standard tooling lowers sourcing risk and supports consistent quality. Brunk’s supply chain and quality teams maintain approved libraries and process controls to guide material selection—from stainless steel to engineering plastics—to meet technical requirements and schedule targets.

Reduce part count. Fewer parts mean fewer interfaces, less variation, and faster assembly. Using DFMA and design for additive manufacturing, we consolidate features, cut fasteners, and define intuitive build sequences. When appropriate, 3D printed metal can merge complex sub-assemblies, while machined prototypes confirm manufacturability before committing to tooling.

Why Implement Design for Manufacturing with Brunk?

Cost reduction: DFMA exposes cost drivers early—tight tolerances that aren’t needed, complex features, or non-standard materials—before they lock in. By simplifying design, consolidating parts, and using standard tooling, Brunk reduces tooling complexity, scrap, and assembly steps. Our design engineering reviews align process choices and material selection with budget and performance targets.

Quality and reliability: Designing for process capability stabilizes outcomes from first article to full-scale. DFMA-informed decisions—wall thickness, draft, gate placement, datum schemes—improve dimensional and cosmetic consistency. Brunk uses metrology, capability studies, and FEA to translate design for manufacturing guidance into repeatable production with strong Cp/Cpk and fewer corrective loops.

Speed to market: When manufacturability is built in, rapid prototype cycles shrink and qualification moves faster. Our integrated tooling, machining, machine to stamping, and assembly teams provide immediate feedback, so part files are production ready. That shortens pilot runs, smooths PPAP, and supports confident scale-up—without late-stage surprises.

How to Integrate DFMA Into Your Project

Start with early DFM analysis. We evaluate geometry, processes, and supplier capability to identify risks in tolerances, cost, and material selection before they become expensive to change. Brunk engineers review features and operations to simplify designs, reduce part counts, and match requirements to practical methods—from pcb board fabrication and stainless-steel stampings to 3D printed metal and machined prototypes.

Enable cross-functional collaboration. Bring design engineering, manufacturing, quality, and supply chain together to define critical-to-quality features and acceptable tolerances. With shared context, teams select standard tooling, allocate tolerances with FEA, and consolidate operations. Brunk facilitates structured design reviews and lunch and learn sessions to align product intent with process realities and accelerate approvals.

Build iterative validation. Prototype early, measure with real process data, and refine quickly. Use first-article inspections, capability studies, and pilot runs to confirm manufacturability and durability. Our rapid prototype services and PPAP support create feedback loops that improve design metrics, stabilize costs, and ensure a smooth transition to volume production.

DFMA and Industry 4.0

Connected equipment, sensors, and digital twins bring live capability data to design for manufacturing. Engineers can validate geometry and tolerances sooner and adjust solid modeling based on actual cycle times, scrap rates, and tool wear. Brunk integrates machining, molding, machine to stamping, and pcb board fabrication insights into the design phase to optimize throughput and yield.

Data-driven DFMA decisions matter. We use statistical trends and FEA to guide tolerance allocation, fixturing strategies, and material selection. Design for additive manufacturing helps unlock geometries for 3D printed metal or hybrid approaches that shorten lead times. Brunk’s engineering workflows turn production analytics into actionable design metrics that you can trust.

Design for automation. Parts optimized for robotic handling, inspection, and assembly reduce variability and labor content. That means simplifying interfaces, controlling finishes, and standardizing datum schemes compatible with vision systems and automated gauging. Brunk applies DFMA and design for additive manufacturing to enable faster changeovers, reliable quality, and seamless movement from rapid prototype to production.

Common DFM Challenges and How Brunk Solves Them

Balancing creativity and manufacturability: Treat constraints—process capability, tolerances, and materials—as design boundaries that sharpen innovation. Early feasibility reviews, production-aware solid modeling, and feedback from machined prototypes help refine geometry without sacrificing brand or function. At brunk.com, we align aesthetic goals with DFMA realities to prevent late-stage redesigns.

Closing communication gaps: Misalignment among design engineer, quality, and operations creates errors and delays. Clear documentation, revision control, and shared design metrics keep teams in sync. Brunk’s structured handoffs, lunch and learn sessions, and manufacturability checklists foster transparency from concept to launch.

Managing supply chain risk: Availability and capability should shape design from the start. Selecting standard tooling and materials, designing for multiple qualified processes (including machine to stamping and pcb board fabrication), and defining acceptable substitutes mitigate risk. Brunk partners with vetted suppliers and uses demand forecasting to keep new product development on schedule.

From Prototype to Production: Key Capabilities

Additive manufacturing: Design for additive manufacturing accelerates iteration and consolidates parts where it makes sense. Brunk supports 3D printed metal for complex, production-intent geometries and bridges to machining and stamping as volumes rise.

Machining and stamping: Precision CNC and machine to stamping deliver cost-efficient parts at higher volumes. We validate with machined prototypes, confirm FEA assumptions, and lock in design metrics before scaling with standard tooling.

Electronics and assemblies: For pcb board fabrication and integrated assemblies, DFMA reduces rework by aligning form, fit, and function with soldering, placement, and test strategies. Material selection and tolerance stacks are tuned for reliable throughput.

Materials and finishes: From stainless steel to engineered plastics, we help you select materials that hit performance and cost targets. Surface finishes and datum schemes are defined to support automated inspection and repeatable quality.

Partner with Brunk: A Trusted Leader in Design for Manufacturing

Brunk blends design engineering rigor with real production insight. Engage us early and get a partner who translates design into repeatable, scalable results. Our integrated teams cover DFMA, design for additive manufacturing, solid modeling reviews, FEA, machined prototypes, 3D printed metal evaluations, machine to stamping, pcb board fabrication, and PPAP. We focus on measurable design metrics, smart material selection, and standard tooling strategies that minimize cost, improve quality, and speed market entry.

Ready to move? Book a lunch and learn with our applications engineers or send your CAD for a rapid prototype and DFM review. Brunk is the trusted choice for new product development—fast, reliable, and production-ready.

Contact our sales team to discuss your next project.